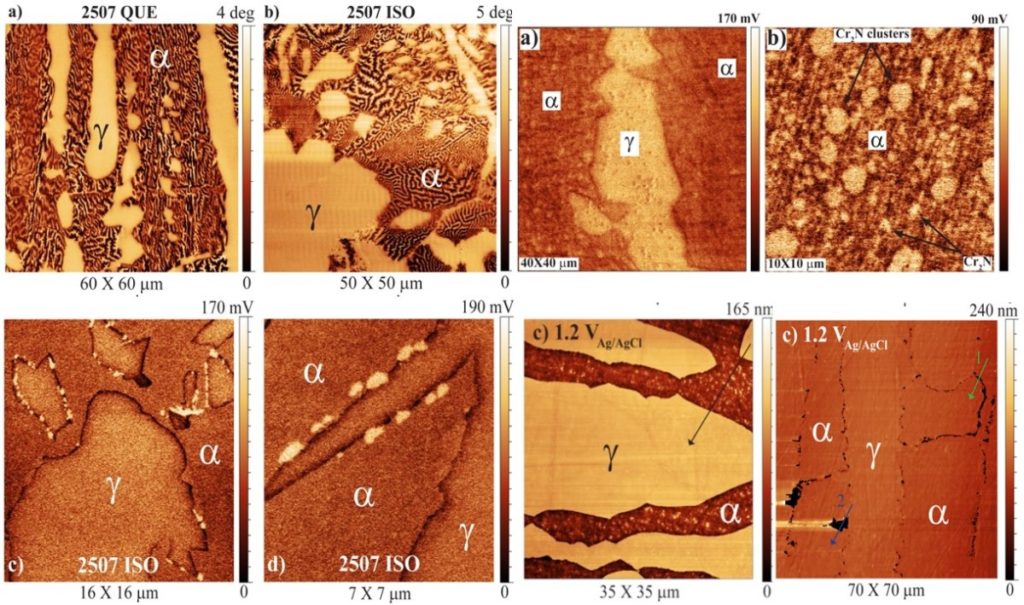

Advanced alloys often have complex microstructure to achieve high performance. Duplex stainless steel (DSS) is a good example of this type of alloy. In addition to ferrite (a) and austenite (g) phases, precipitates such as sigma phase and chromium nitrides may form in DSS during processing, which strongly influence the corrosion behaviour. We have used ex-situ and in-situ AFM techniques to evaluate the relative nobility (corrosion tendency) of microstructure features and to study the influence of nano-sized chromium nitrides on corrosion initiation.

Magnetic force microscopy (MFM) and scanning Kelvin probe force microscopy (SKPFM) were used for characterization of different phases including ferrite, austenite, sigma phase, and chromium nitrides in DSS. MFM maps revealed different magnetic properties of ferrite and austenite, allowing easy phase identification. MFM and SKPFM images of the same area provides information of the location of micro- and nano-meter sized precipitate particles and their corrosion tendency relative to the surrounding matrix. The ex situ and in situ electrochemical AFM studies suggested that isothermally precipitated Cr nitrides (80 - 230 nm in size) at ferrite/austenite phase boundaries could be detrimental, whereas small quenched-in Cr nitrides (50 - 100 nm in size) formed inside the ferrite seemed to have little or no effect on the corrosion behavior.

References

Electrochimica Acta, 113, 280 (2013).DOI: 10.1016/j.electacta.2013.09.056Intern. J. Electrochem.Sci., 9, 61 (2014). link

Technique Guides