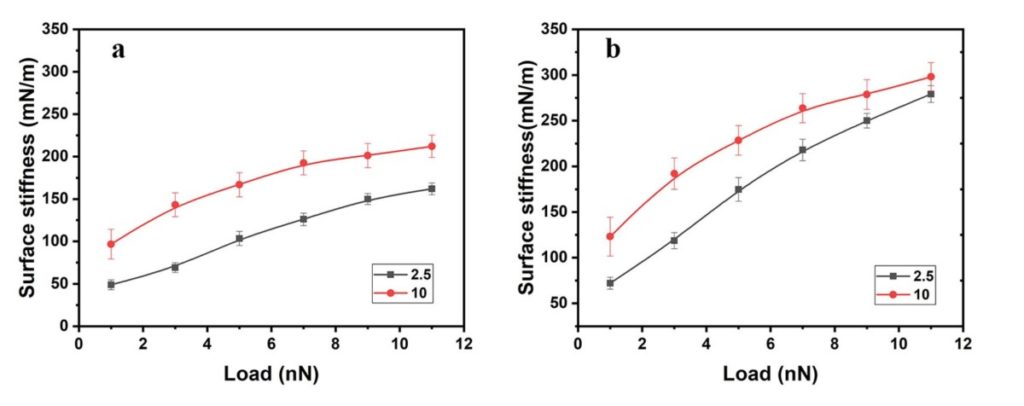

Hydrogel materials are very soft when immersed in water, and it is relatively difficult to measure their mechanical properties in aqueous solutions. We have, however, done this by means of atomic force microscopy, AFM, using sharp tips and colloidal probes. Investigations are possible both on microgel particles and on films of hydrogel materials, and for apparent elastic moduli down to the 100 kPa range. We use the term apparent elastic modulus since hydrogel materials are viscoelastic and viscous properties are most often ignored when evaluating the data in terms of elastic modulus. Since the material is viscoelastic it means that both the compression rate and the degree of compression (i.e. the load) affects the data. Due to the inaccuracy of elastic models for these systems we prefer to report surface stiffness rather than elastic modulus, as surface stiffness is measured directly, while elastic modulus is obtained by fitting the data to a model. Hydrogels appear stiffer on decompression than on compression, a fact that depends on the impaired diffusion of water in the network structure. It is thus appropriate to evaluate the mechanical response on both compression and decompression as well as using different loads and compression speeds. Such behaviour was recently investigated using polyHEMA hydrogel films.